Industrial Hollow Shaft Magnetic Particle Powder Brake

The outer diameter and axial dimensions of hollow shaft magnetic powder brake series products are small, and the hollow shaft occupies a small area, which can be conveniently installed on the machinery. The rotating body is covered by the stationary part, so the natural cooling effect is small, but the heat capacity can be increased by forced air cooling.

Description

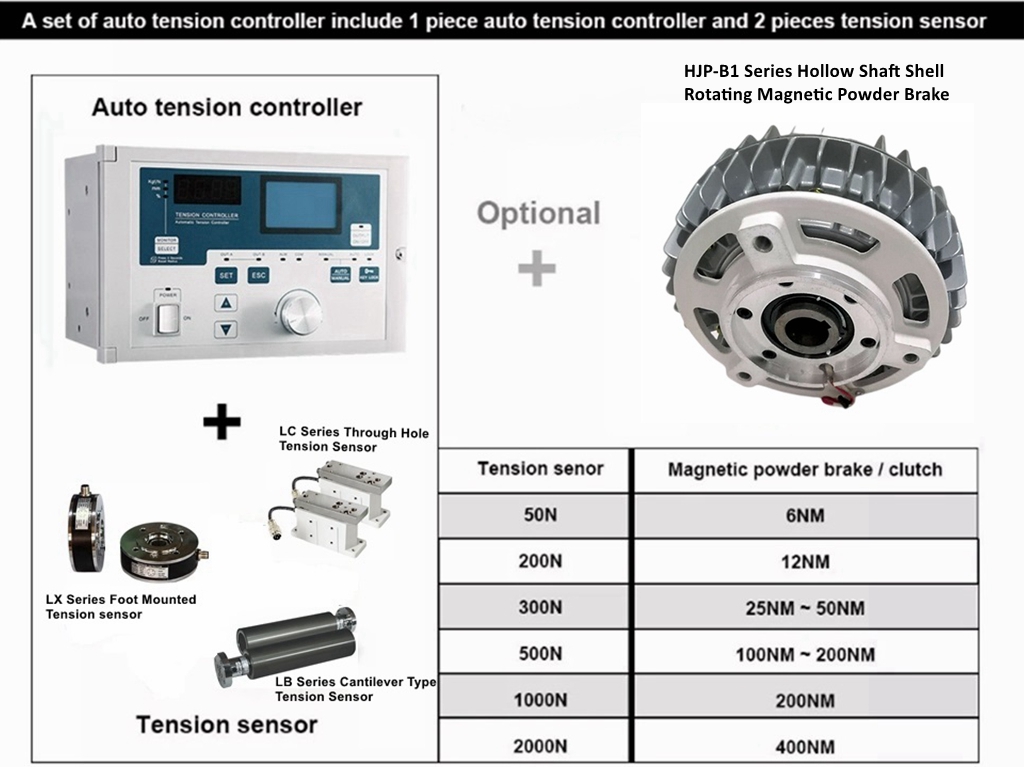

Hollow Shaft Shell Rotating Magnetic Powder Brake

| Brand Name: | HJP-B1 Series |

| Application: | For all kinds of printing & converting machines need unwinding |

| Voltage | 24V DC |

| MAX Rotation Speed | 1000rpm/min |

| Rated Torque | 0.6kgfm–40kgfm |

| Current | 0.3A-2.2A |

| Colour: | Gray |

Magnetic powder brake is based on electromagnetic principle and uses magnetic powder to transmit torque. It has the characteristics that the excitation current and the transmission torque are basically linear. It can transmit a certain torque when it is independent of the slip, and has the advantages of fast response, simple structure, no pollution, no noise, no impact and vibration, energy saving, etc. It is a multi-purpose, high-performance automatic control element.

It has been widely used in unwinding and winding tension control in papermaking, printing, plastics, rubber, textile, printing and dyeing, wire and cable, metallurgy, tablet press and other related winding processing industries.

Introduction to Magnetic Powder Brake HJP-B1 :

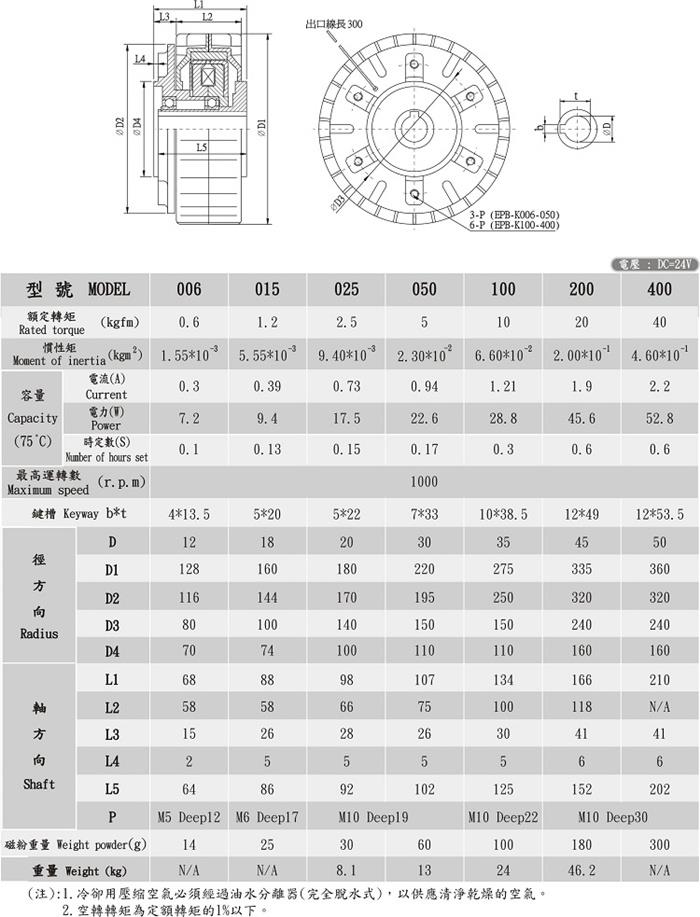

Catalogue:

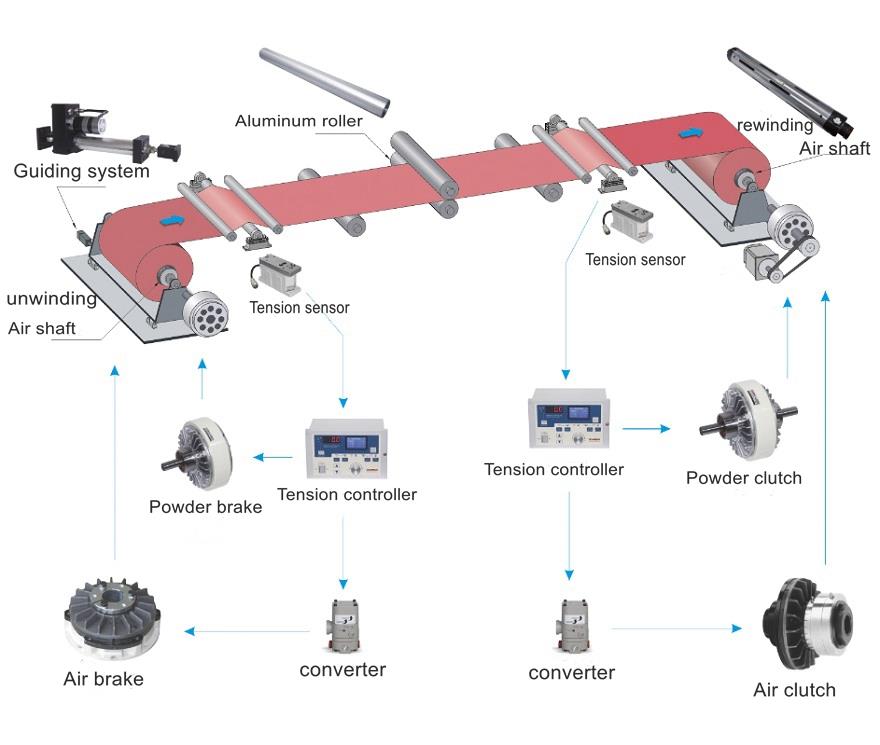

Magnetic powder brake installation example diagram:

The Schematic Diagram of powder brake,tension control, web guide system and other parts on equipment.

Correct use of hollow shaft magnetic powder brake:

1. When the hollow shaft magnetic powder brake and clutch are used as continuous sliding for coiling and unwinding, the product and service life will vary depending on the service conditions (relative sliding speed, etc.). But generally speaking, the service life of iron powder when reducing the freezing torque in the freezing current is about 4500-7500 hours. However, in some cases, it can not be used below the freeze frame torque, so it can continue to be used, and the service life can be further extended. However, even if the sliding working rate is the same, when the sliding rotation speed, that is, the relative rotation speed is continuously high, the service life tends to decrease, so the setting time should focus on reducing the relative rotation speed.

2. In order to prolong the service life of iron powder, it is also a way to make the allowable sliding working rate more abundant.

3. If the driven member is taken as the input side, it will continue idling for a long time, and the iron powder will be stirred, and the service life will be greatly reduced. Please avoid this method as much as possible. If it is unavoidable in structure, please set the current to the weak excitation state when using. When running at low speed (below 16RPM), it will produce stable torque characteristics when it is used for continuous operation such as tension control.

1. Even at the end of coiling, continue to give weak excitation (7-150% of the fixed current) to prevent the iron powder from falling from the action surface;

2. Please increase the low rotation speed to 16RPM after increasing speed.

Application:

Order Details

| Item Name | HJP-B1 Hollow Shaft Shell Rotating Magnetic Powder Brake |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 3-5 days after receiving the deposit |

| Calculated Weight | According to different models |

| Package | Carton/Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |