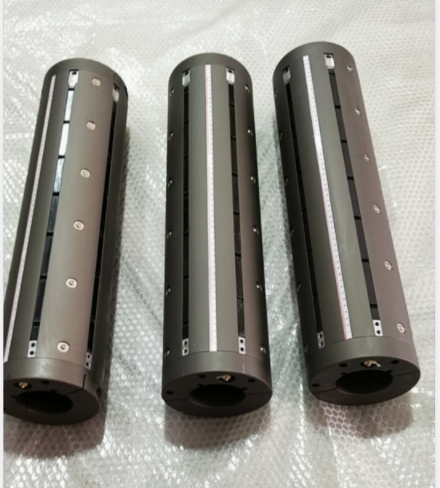

High presion Nishimura type differential slip shaft

Differential air shaft is mainly used for sub-section equipment that has high requirement on final products and fast speed.The differential ring on it can slip independently. Controlled by the tension system, let the compressed air which has a certain pressure come to axle core, so that it will produce friction torque between the friction parts and the slip ring, and realize constant tension coiling and it will help solve the unwinding problems and material damages caused by uneven thickness and tension of each roll material.

Description

Introduction

Known as slip shaft, differential shaft and friction shaft, it is mainly used as the winding shaft of the slitter and the unwinding shaft of special products. The friction force of the slip shaft is adjusted by the air pressure.

Differential air shaft is mainly used for sub-section equipment that has high requirement on final products and fast speed.The differential ring on it can slip independently. Controlled by the tension system, let the compressed air which has a certain pressure come to axle core, so that it will produce friction torque between the friction parts and the slip ring, and realize constant tension coiling and it will help solve the unwinding problems and material damages caused by uneven thickness and tension of each roll material.

-300x300.jpg)

Structure

Central air pressure differential shaft are made of core roll, differential ring, airbags, friction parts, sealing rings.

The relationship between air pressure and torque

|

Air pressure |

Torque |

|

0.1MPa |

0.81N.m |

|

0.2MPa |

1.35N.m |

|

0.3MPa |

1.58N.m |

|

0.4MPa |

1.92N.m |

|

0.5MPa |

2.25N.m |

|

0.6MPa |

2.42N.m |

|

0.7MPa |

2.62N.m |

|

0.8MPa |

2.93N.m |

The Nishimura friction shafts is not only a vital part of the winder,such as drying machine, flexo printing machine, gravure machine, trademark printing machine, coating machine, leather machine, setting machine, embossing machine, slitting machine, die cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, film blowing machine, foaming machine,embossing machine, paper machine, non-woven machine, cloth inspection machine, bronzing machine, battery device, and the like are all required. The quality of differential shaft is a good consideration for production.

Technique parameter

| Model | Paper tube inner diameter | Shaft diameter before expanding | Shaft diameter after expanding | Number of pistons |

| 3″ Differential Shaft | Φ76mm | Φ75mm | Φ78mm | 8 :(for slitting of packaging film and general film);

12: Suitable for lithium battery pole pieces, slitting of diaphragm; 16: Suitable for wide lithium foil of power lithium battery, slitting of aluminum foil. |

| 6″ Differential Shaft | Φ152.4 | Φ151mm | Φ156mm |

Application of differential air shaft

A.The applicable Machine

It is used for slitting machine,coating machine,cutting machine,printing machine,compounding machine,paper making machine,bag makeing machine, embossing machine and so on .It can greatly improve the working efficiency and the quality of products.

B.The applicable Material

Differential air shaft has been widely used in plastic film including electronic, capacitor, battery film, plastic wrap, packaging, composite film, metal foil such as copper foil and aluminum foil, paper and pvc sheet.

Packaging

Order Details

| Item Name | Nishimura Type Differential Shaft |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 30 days after receiving the deposit |

| Calculated Weight | Need to count |

| Package | Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

.jpg)