All kinds of high-quality high-temperature bronzing silicone rubber rollers

The rubber roller is generally composed of outer layer rubber, hard rubber layer, metal core, roller neck and vent hole. Its processing includes roller core sandblasting, bonding treatment, glue forming, wrapping cloth, wire winding, vulcanization tank vulcanization and surface processing. and other processes. Rubber rollers are mainly used in papermaking, printing and dyeing, printing, food processing, metallurgy, plastic processing and so on.

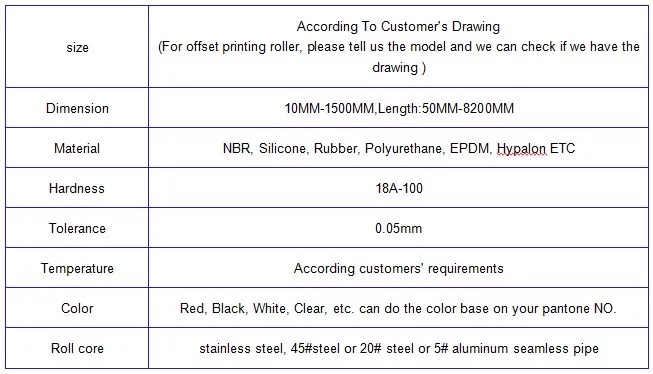

Description

The rubber roller is generally composed of outer layer rubber, hard rubber layer, metal core, roller neck and vent hole. Its processing includes roller core sandblasting, bonding treatment, glue forming, wrapping cloth, wire winding, vulcanization tank vulcanization and surface processing. and other processes. Rubber rollers are mainly used in papermaking, printing and dyeing, printing, food processing, metallurgy, plastic processing and so on.

According to the use, it can be divided into: papermaking rubber roller, printing and dyeing rubber roller, printing rubber roller, grain hulling rubber roller, metallurgical rubber roller and mimeograph rubber roller, etc.;

Good wear resistance

High tensile strength

Anti-static

High load capacity

High-temperature resistant

Excellent dynamic mechanical formulation

Oil resistance

Solvent resistance

Hydrolysis resistance

antioxidant

Relative roller and shaft

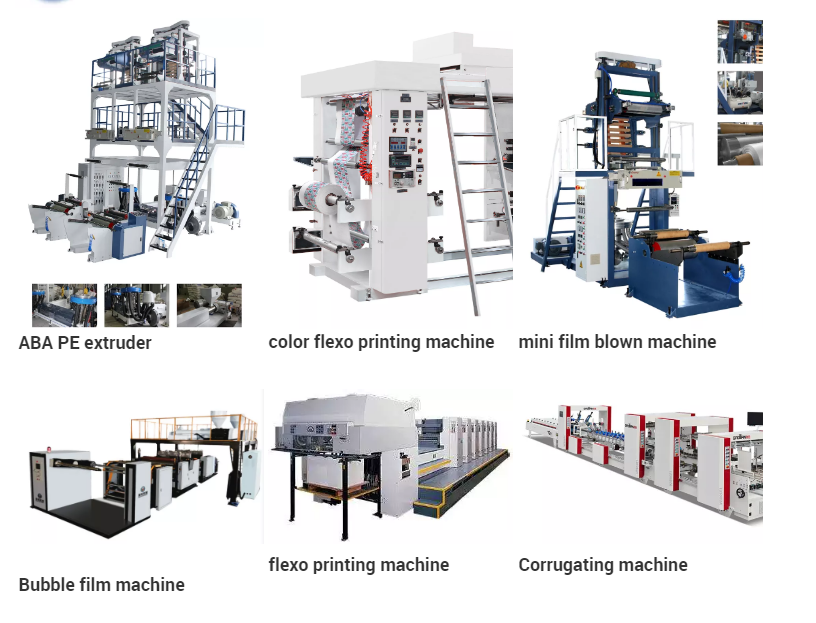

Application

Packaging

Order Details

| Item Name | PU roller |

| MOQ(Minimum Order Quantity) | 1PC |

| Lead time | 7-15 days after receiving the deposit |

| Calculated Weight | Need to count |

| Package | Wooden Box/Pallet packing/according to clients’ requirement and demand |

| Price Term | EXW, FOB, CIF, etc |

| Payment term | TT, L/C, Western Union |

| Country of Origin | China |