KTC-838A Automatic Tension Controller with Taper and Communication for unwind rewind

KTC-838A tension controller adopts a new graphic LCD display, which can display more clearly in Chinese and English. It sends out a 0~24VDC control voltage command for magnetic particle clutch/brake, and can also output a 0~10V voltage signal to control the inverter, servo motor or other actuators to conduct high-precision tension control on the coil. It is widely used in printing, packaging, paper making, cable, rubber and plastic, electronic battery, textile printing and dyeing and other industries.

Description

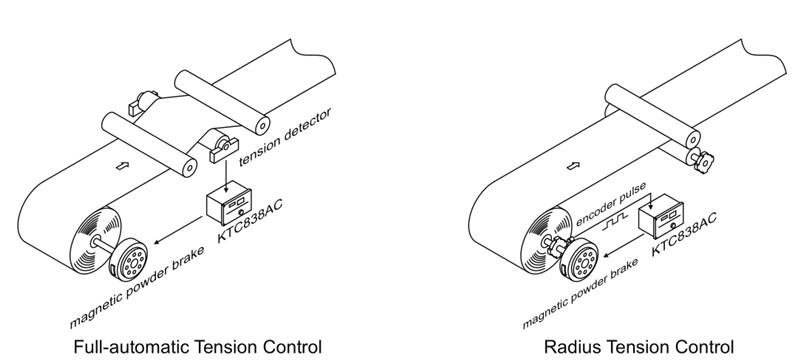

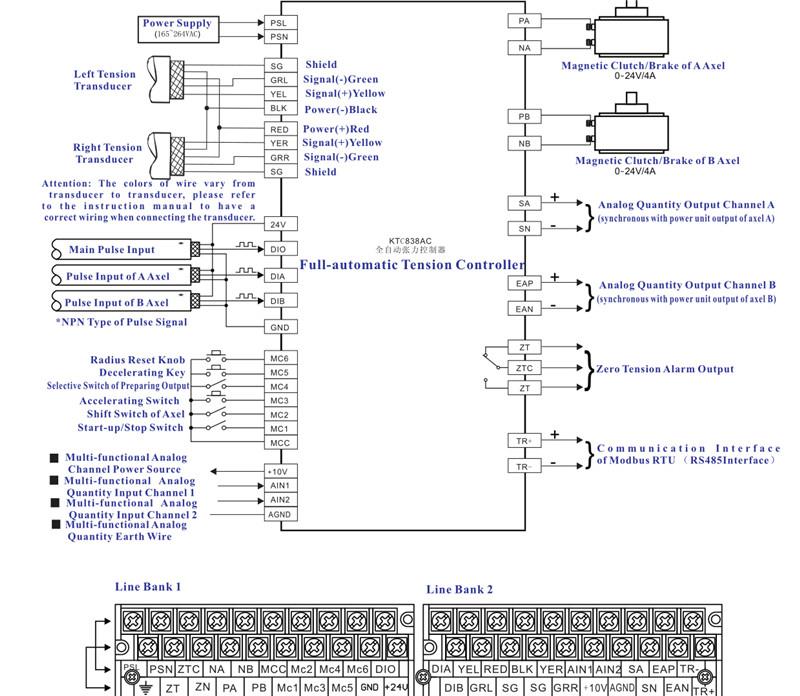

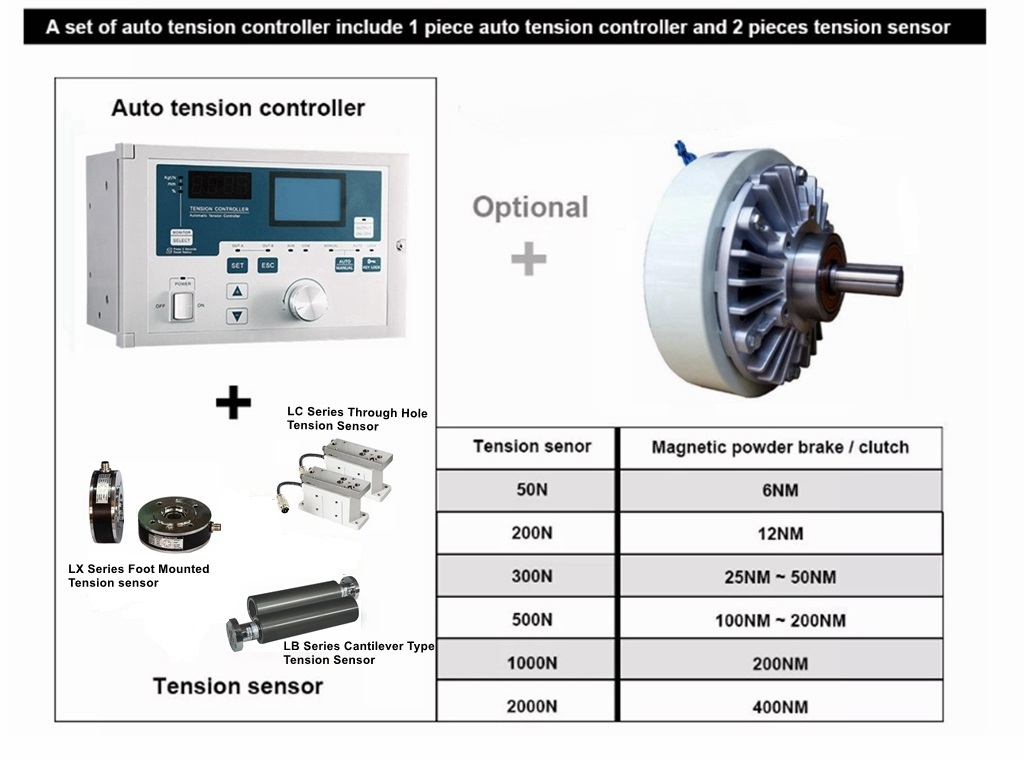

The full-automatic tension controller KTC838A is a high-precision, multi-functional, fully digital intelligent tension controller. It can cooperate with the tension detector to form a closed loop tension control system, or form an open loop tension control system by automatically calculating the tension through a proximity switch/encoder. That is, it has the functions of KTC818A and KTC828A at the same time, providing users with more free choices.

KTC-838A tension controller adopts a new graphic LCD display, which can display more clearly in Chinese and English. It sends out a 0~24VDC control voltage command for magnetic particle clutch/brake, and can also output a 0~10V voltage signal to control the inverter, servo motor or other actuators to conduct high-precision tension control on the coil. It is widely used in printing, packaging, paper making, cable, rubber and plastic, electronic battery, textile printing and dyeing and other industries.

Functional features

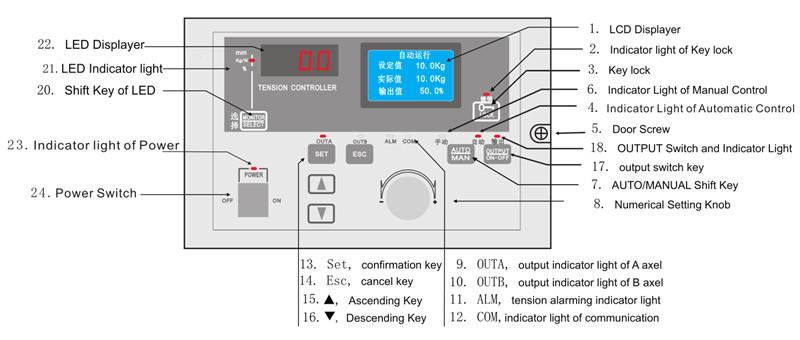

1. 128×96 graphic LCD is adopted, with Chinese and English display options, and the operation interface is friendly.

2. Digital design, no adjustable potentiometer, simple tension calibration process, accurate, stable and reliable tension measurement.

3. It can receive input signals from single/dual sensors and adapt to various tension sensors as input signals:

a. Differential special tension sensor can be selected (input signal range is 200mV, power supply is 5V)

b. Strain gauge tension sensor can be selected (input signal range is 20mV, power supply is 10V)

c. Angle potentiometer can be used as floating roller tension control.

4. It can realize the taper tension control function, support the thickness accumulation, and measure the roll diameter by the ratio method.

5. Optional serial communication function, optional RS485 communication interface, PLC and PC form a distributed system (optional communication function).

6. PID algorithm without overshoot is adopted to ensure no overshoot of tension during system startup/shutdown.

7. It has dual axis switching function and acceleration/deceleration control function.

8. Automatic/manual control undisturbed mode switching.

9. Parameter password protection to prevent incorrect modification.

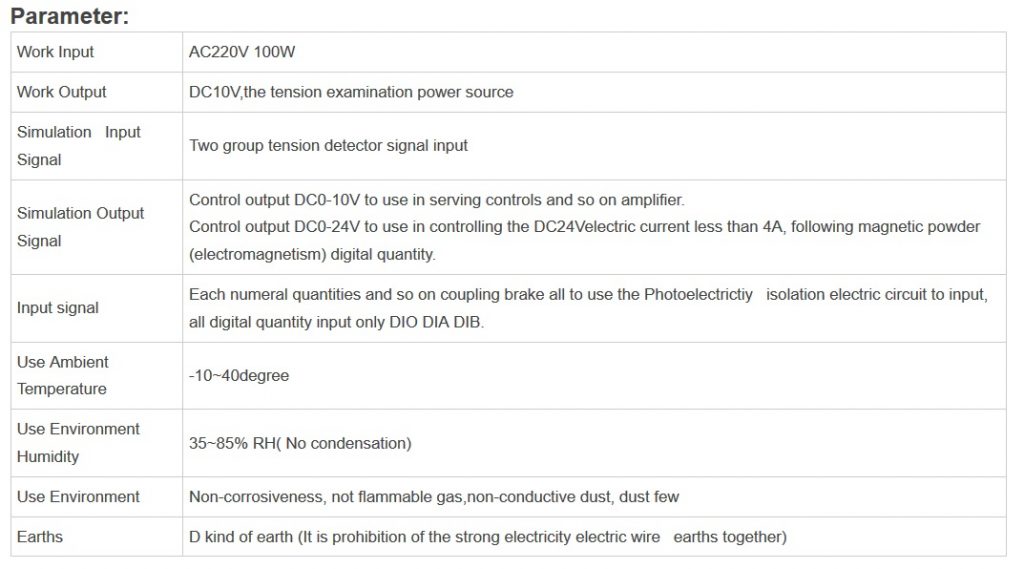

10. The switching power supply (165-264VAC) with strong adaptability is adopted to ensure long-term reliable operation.

Operating panel

Wiring Diagram:

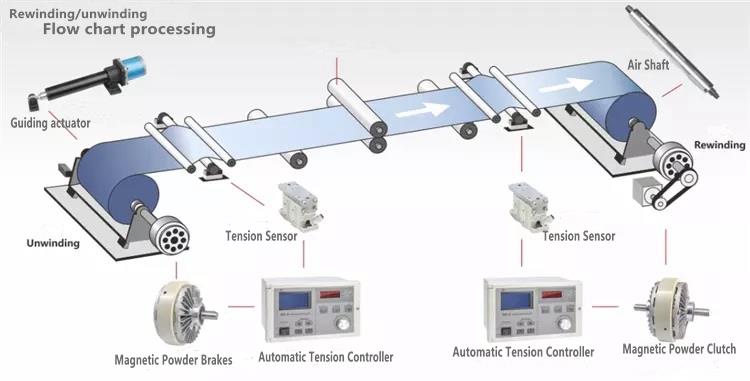

The main application field of tension controller. In life, tension controller is a kind of equipment that can permanently control the tension capacity of the material belt when it is transported on the equipment. The use of such equipment can well maintain the running speed of the equipment, and can keep the production unaffected in an emergency. How does this device work?

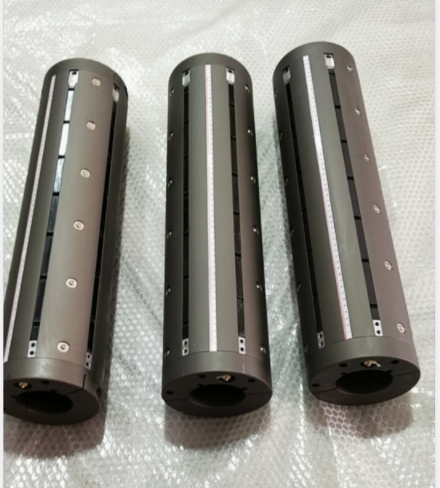

The tension controller mainly works through the coil. The coil static magnetic powder clutch and magnetic powder brake are automatic devices that control the input current to change the output torque. When the coil is not powered on, the input shaft rotates, the magnetic powder is pressed on the inner wall of the clamping ring under the action of centrifugal force, and the output shaft is not in contact with the input shaft. At this time, it is idling. When the coil is energized, the magnetic particle will generate flux linkage under the action of magnetic force line, so that the output shaft and input shaft will become a rigid body and rotate, and slip will occur when the coil is overloaded. This is the working state. So as to achieve the purpose of transmitting torque.

Product Application

* Printing systems: conveyors and in-feeders

*Wood-working systems: saws, wood-working machine, laminators

* Office equipment: electronic copy machines, calculators, fax machines, coin counters, printers

* Testing systems: lab machines, durability testers, measuring systems

* Food processing systems: meat cutting machines, cookie making machines, canning machines, noodle making machines

* Others: speed reducers, electroplating machinery, physics and chemistry machines, paper-making machines, pulp processing machines.

Order Details

| Item Name | KTC-838A Automatic Tension Controller with Taper and Communication Function |

| MOQ(Minimum Order Quantity) | 1pc |

| Lead time | 2 days after receiving the deposit |

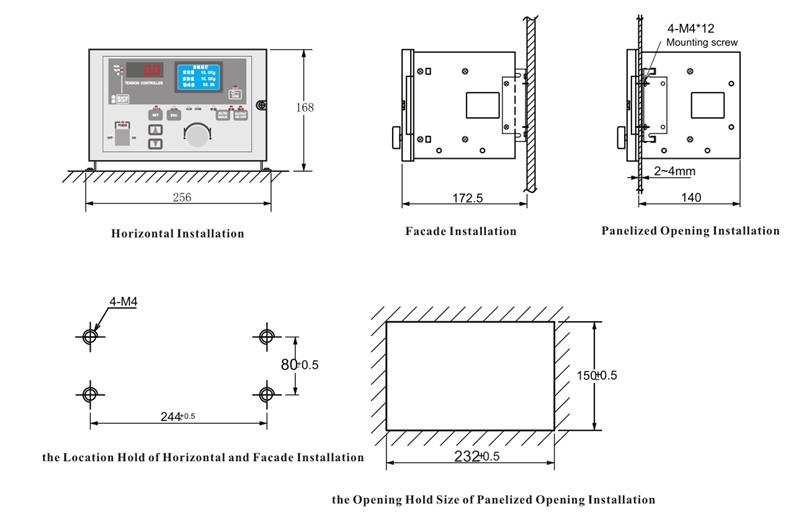

| Calculated Packing Size | 20cm*15cm*15cm,2kg/pc |

| Package | Carton |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |