Outer Shell Rotating Magnetic Powder Clutch for Rewinder

The magnetic particle clutch and brake have the above characteristics, and are now widely used in the unwinding and winding tension control in papermaking, printing, plastic, rubber, textile, printing and dyeing, wire and cable, metallurgy and other related coiling processing industries. In addition, the magnetic particle clutch can also be used for buffer starting, overload protection, speed regulation, etc. Magnetic powder brake is also often used for dynamometer loading and braking of transmission machinery

Description

Hollow Shaft Shell Rotating Magnetic Powder Clutch

| Brand Name: | HPJ-A1 Series |

| Application: | For all kinds of printing & converting machines need rewinding |

| Voltage | 24V DC |

| MAX Rotation Speed | 1000rpm/min |

| Rated Torque | 0.6kgfm–20kgfm |

| Current | 0.7A-2.5A |

| Colour: | Gray |

Introduction:

HPJ-A1 Model: 6N.m 12N.m 25N.m 50N.m 100N.m 200N.m

The magnetic particle clutch and brake have the above characteristics, and are now widely used in the unwinding and winding tension control in papermaking, printing, plastic, rubber, textile, printing and dyeing, wire and cable, metallurgy and other related coiling processing industries. In addition, the magnetic particle clutch can also be used for buffer starting, overload protection, speed regulation, etc. Magnetic powder brake is also often used for dynamometer loading and braking of transmission machinery

Catalogue:

Features

1. Magnetic powder clutch and brake are a kind of automatic control components with superior performance.

2. It has high linearity and high precision torque control.

3. The use of high temperature resistant coil super alloy magnetic powder, long service life, smooth connection, no impact magnetic powder clutch

4. CNC precision manufacturing, high precision, fine processing, good linearity and superior performance.

5. The magnetic powder has high purity, no black carbon powder, stable performance and long life.

6. Aluminum alloy structure, with excellent heat dissipation performance, good demagnetization, and fast response speed.

7. Stable operation, no vibration, no impact, no noise under starting, running and braking conditions.

8. The torque is proportional to the excitation current within the specified torque range, and it can be used as a linear adjustment element.

9. The output torque is constant, because the magnitude of the torque only depends on the magnitude of the exciting current, and has nothing to do with the slip speed.

10. Frequent closing and closing, fast response speed, high frequency, up to 40-60 times per minute, can be widely used in fast working conditions and high frequency occasions. 11. The power magnification is high, and a very small excitation current can be used to control a large transmission power, and it is easy to realize automatic control.

12. Smooth operation, no vibration, no impact, and no noise under starting, running, and braking conditions.

13. Overload protection. In the case of torque overload, the automatic slip operation plays a role of overload protection.

14. Small size and light weight. Easy installation and long service life.

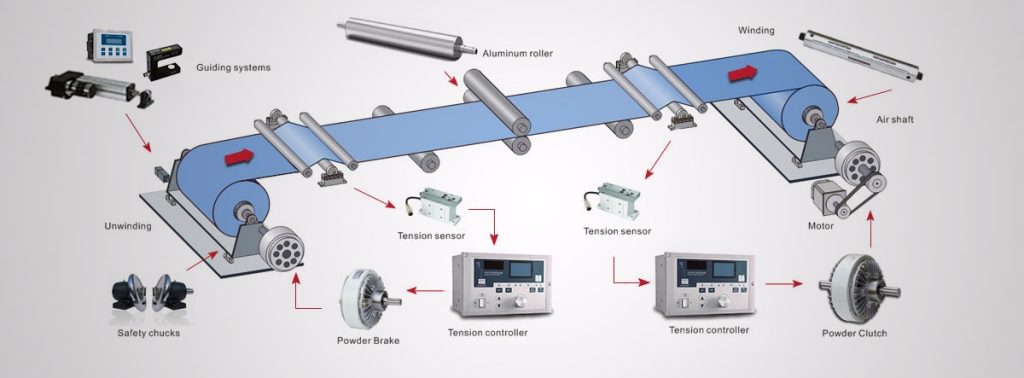

Magnetic clutch installation example diagram:

The Schematic Diagram of powder clutch,tension control, web guide system and other parts on equipment.

Application of Magnetic Powder Clutch:

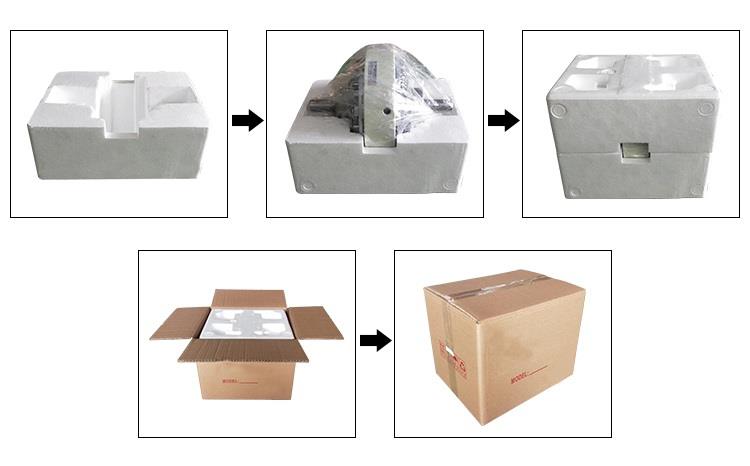

Packaging

Order Details

| Item Name | HPJ-A1 Hollow Shaft Shell Rotating Type Magnetic Powder Clutch |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 3-5 days after receiving the deposit |

| Calculated Weight | According to different models |

| Package | Carton/Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |