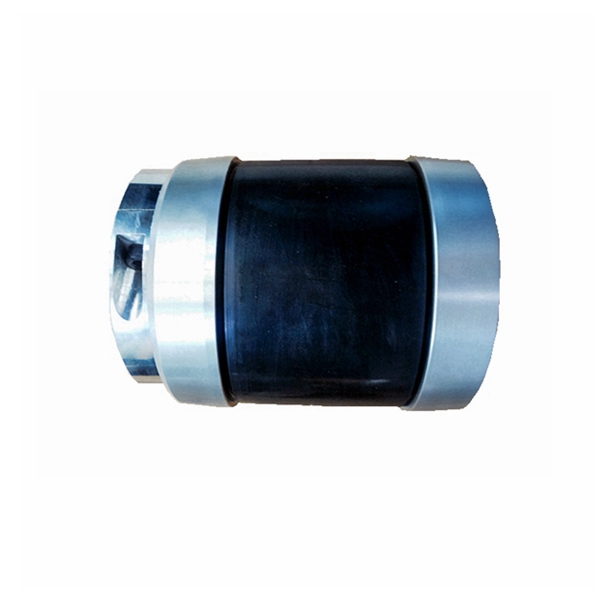

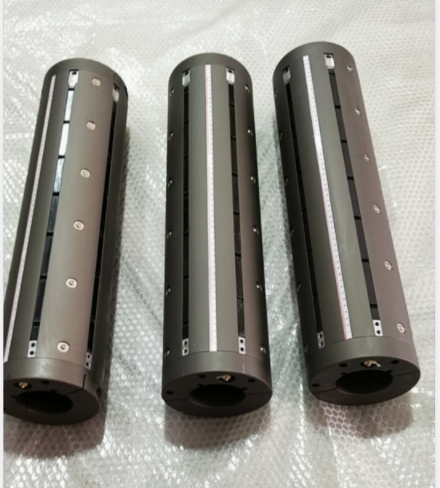

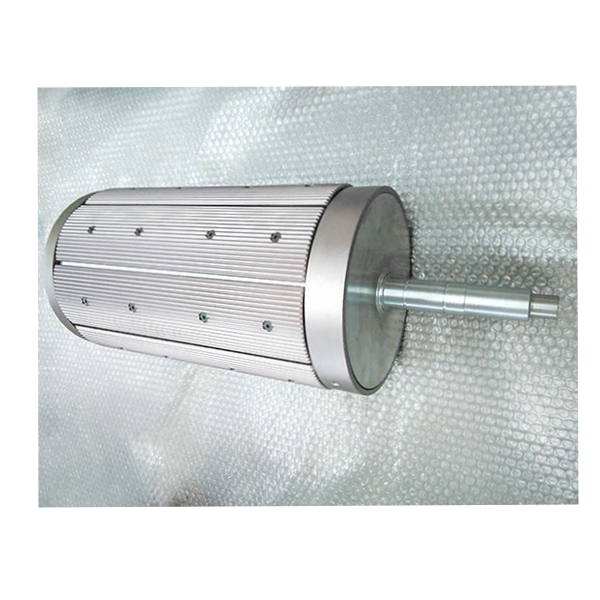

3 Inch Pneumatic Mechanical Core Chuck

Equipped with pneumatic mechanical mechanism to ensure perfect clamping of the core, safe operation, durable and flexible. Pneumatic mechanical chuck is usually used in industries with large roll diameter and high load, such as corrugated board production.